Welcome to our Industrio!

Coating Technologies

Bisco a pioneer in advanced coating technologies, continually works to improve our applications and procedures and always keep ourselves and our customers updated about the latest development in the Metal Finishing Industry. Our leadership is proven time and time again with the development of processes, equipment and with our high level of commitment to the customer.

Electrocoating

The e-coat process offers you many advantages. Those advantages start with an appropriate pretreatment, move on to careful electrocoating, and finish with thermal curing.

- More industries than ever before are selecting electrocoating for the following reasons: Excellent Finish Quality, High Productivity, Cost-Effectiveness, High-Efficiency, and Versatile Technology Options

- In addition, electrocoating offers an “environomic” solution-no heavy metals, no HAPS and low VOCs.

- Electrocoating provides an excellent base for a variety of topcoats. It provides an incredible “dual application advantage,” creating a more decorative and durable finish. As a leading coatings applicator,we at Bisco provide the technology, leadership and ability to do both processes in-house, serving a broad spectrum of industries and specifications.

- Electrocoating readily conforms to complex configurations and yet maintains engineered tolerances on parts ensuring intended operating functions. Some examples include: Internal Surfaces, Deep Recesses, Weldments, Fasteners, Small Parts, Large Parts, Uniform Coating- No Sags or Runs.

Customers today demand higher quality and durability from the products they buy. Not only do they expect these products to perform well, but they want the finish to look good and resist corrosion for a much longer period of time. The finishing processes offered by Bisco are designed to do just that. One of those finishing processes is electrocoating (e-coating).

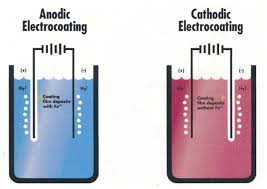

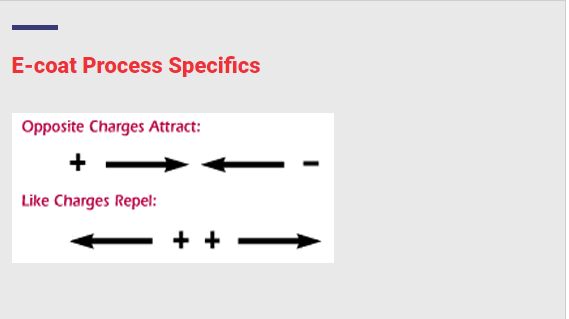

E-coating is a method of painting which uses electrical current to deposit the paint. The process works on the principal of “Opposites Attract”. This process is also known as electrode position.

Powder Coating

Powder coating as a coating technology. Powder coating is different from painting in that there are no liquids or solvents making it the ultimate coating technology for environmental concerns. Being dry, the powder overspray can be reclaimed for an efficient application process. Powder coating uses heat to convert its state The powder coating materials are basically plastics that have been ground into a fine powder. The coating powder is formulated with plastic resins, pigments, flow agents and other special ingredients to provide the desired characteristics of the coating film. from a fine powder into a continuous film and offers a variety of color and decorative options. With proven experience and processes, we at Bisco can handle any coating need as per customer specification.

In addition, Bisco offers an “environomic” solution-no heavy metals, no HAPS and zero VOCs.At Bisco customers are provided with: Quick Response Time, Specialized Coating Systems and Processes, High Production Capability, Versatile Equipment Options, Large and Small Part Capability.

The Powder coating process offers you many advantages. Those advantages start with appropriate pretreatment, continue with careful powder coating, and finish with thermal curing.

Since 1966, Bisco has been committed to developing and providing coating solutions, such as Anodising, Powder coating,PVC Plastisol coatings that are tailor-made to meet the specifications of our customers. As a market-leading coating application specialist, we offer technology, leadership, and an environmentally sound process. Bisco provides the highest quality coating services while striving for continuous improvements.

Selecting the proper pretreatment is essential to ensure coating success. At Bisco pretreatment process features many options to meet most OEM specifications including: Zinc Phosphate, Iron Phosphate, Chrome Conversion Coatings, Chrome and Non-Chrome Sealers.

Substrates Coated

- Cold Rolled/Hot Rolled Steel

- Galvanized Steel

- Iron Castings

- Zinc Castings

- Copper/Brass

- Magnesium

- Aluminum Extrusions and Castings

- Aluminium Pressure Die Castings

We offer powder coating capabilities that include a wide spectrum of colors, thickness, textures, softness, edge coverages, flexibilities, machinabilities, smoothness and temperature ranges. Current options include: Epoxy,Epoxy Polyster, Nylon, PolyVinyl, Polyester TGIC, Polyster TGIC free,Polyurethane, and more as new projects require.

Advantages Powder Coatings

- Environomic Solution

- Excellent Impact and Mar Resistance

- Variable Thickness

- Zinc Castings

- Excellent Weatherabilty

- Colors, Textures, Gloss Level Option

Whatever the coating objective, if it can be met with Powder coating, or other Metal finishing, you can trust the protective coating specialists at Bisco. To know more about us and our process call 9894666900.

Creative Ideas

Customer Statisfaction

All Time Support

24/7 Support

Sed quia non numquam eius modi tempora incidunt ut labore.

Five Good Reasons to be with us for your Metal Finishing needs

Quality

Bisco’s extensive experience in Metal Finishing has a well-deserved for quality that ranks with the best in the industry.

Batch-to Batch Consistency

When it comes to consistency, Bisco’s products exceed the industry norm by a wide margin.

Problem Solving

Since poineering Metal Finishing. Bisco has found effective solutions to hundreds of difficult coating problems.

Customer Service

You can depend on our total package of efficient order handling, prompt delivery and attention to details. It adds up to superior customer service.

Technical Support

We will roll up our sleeves to help make your component look at its best and meet better Chemical, Machanical and functional requirements.

Get in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

222-121-4562

Email us

support@gmail.com